Ysterhout Dot Net

Making 458x1.5 brass

Making 458x1.5 brass

Making 458x1.5 brass

458x1.5 brass to load dummy rounds to test feeding in a custom rifle.

- No 458x1.5 brass. Unobtainium.

- No 458x1.5 die set. Or six months waiting list to have one made.

.458 WinMag brass is plentiful, and easily obtained. .458 WinMag brass can be used to make .458x1.5 Barnes.

You don't need a dedicated for caliber die set if you can find a 375H&H sizer, and a 45 ACP seating screw that fits in your .458 WinMag seating die. In this case, the threads on a Redding .45 ACP seating stem fit a Pacific Durochrome .458 Win Mag seating die.

In pictures, navigate the silde show with the direction arrrows on the image - captions at the bottom ...

2 / 28

Mark the length required, spec calls for 1.5 inches dummy rounds slightly shorter in case reamer is off-spec

3 / 28

Have mini-lathe, will use.

4 / 28

For the first case, some tape to build up the thickness to just over the belt.

5 / 28

Confirm the trim length

6 / 28

Remove the sharp edges

7 / 28

... and on the inside as well

8 / 28

Camera skews perspective, makes long look longer and short look shorter.

9 / 28

Use the first offcut to make a collet to hold the case in the chuck.

10 / 28

Fits nicely to the belt thickness. With the thinner ( original case mouth ) end to the belt, gives very good concetricity.

11 / 28

Case mouth is too thick. Will give on the weakest side.

12 / 28

Pulled, bent out of shape case

13 / 28

Looks fine from the outside, but no longer concentric inside - scrapped

14 / 28

Comparing the case wall thickness at the mouth of the parent case

15 / 28

Thickness at cut-off point is greater, prevents bullet seating

16 / 28

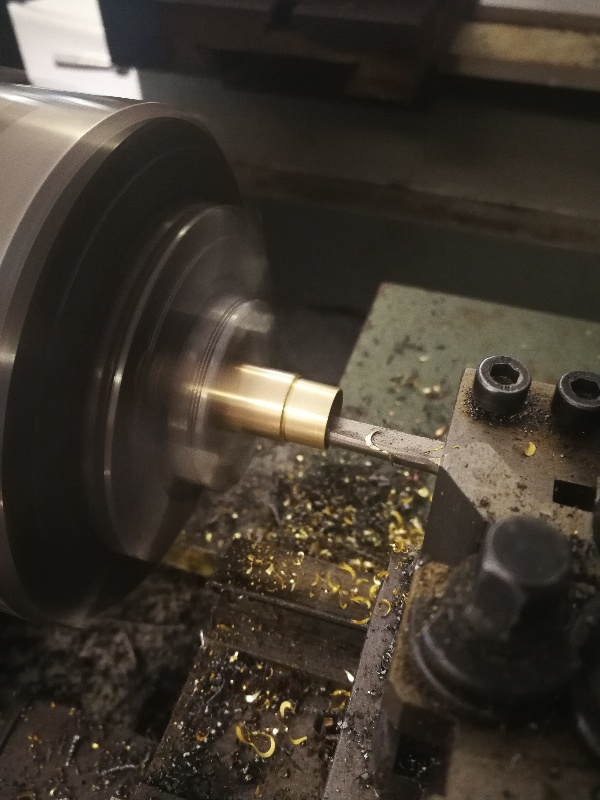

Turn the inside of the case to reduce wall thickness

17 / 28

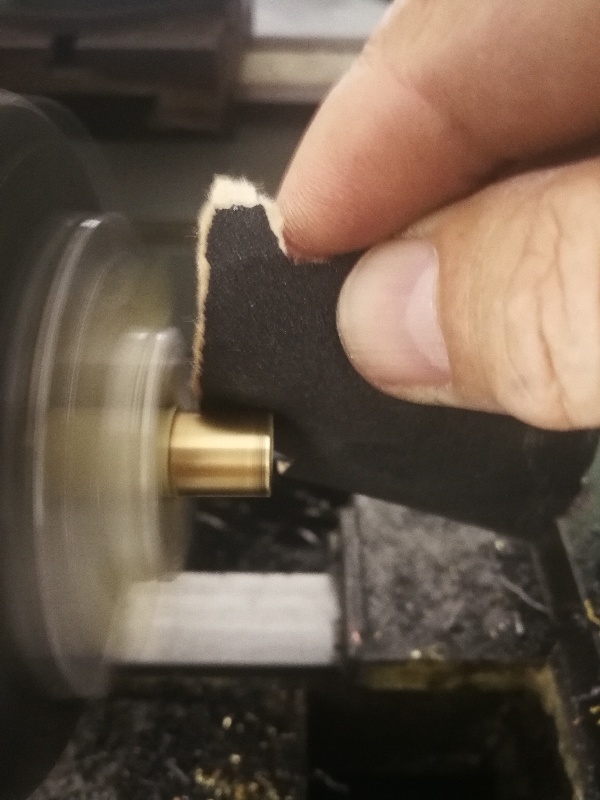

400 grit paper to smooth it a bit

18 / 28

Better - seating should be no problem now

19 / 28

Trimmed cases with necks inside turned

20 / 28

Full length sizing with a 375 H&H die produces the correct taper on the case.

21 / 28

Spec states 0.485 inches max

22 / 28

Redding 45 ACP seating screw [right] is longer compared to Pacific Durochrome 458 Win Mag screw, left. Identical threads.

23 / 28

Seating screw from Redding 45 ACP into Pacific Durochrome 458 WinMag

24 / 28

Trimmed case to 500 grain .458 solid comparison

25 / 28

Bullets seat correctly after inside-neck turning

26 / 28

Size comparison to 600 grain cast

27 / 28

500 grain solid and 600 grain cast

28 / 28

Freebore will limit OAL. Spec provides for 0.1 inches, then tapers 2 degrees over the next one inch.

Making 458x1.5 brass

Making 458x1.5 brass

Last Updated 14 January 2025 8:14:12 GMT+2