Ysterhout Dot Net

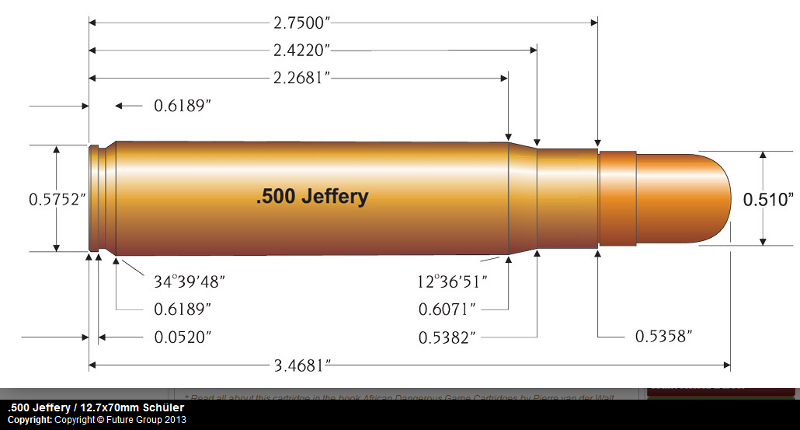

Reloading the .500 Jeffery

with Somchem powders and South African bullets, specifically to make Ultra Bore power factor in the BASA shoots.

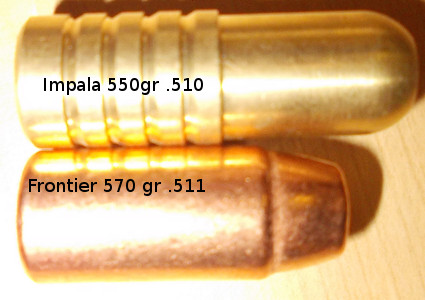

The most economical commercial bullet available that used to be available South Africa for the 500 Jeffery was the Frontier 570gr. This was discontinued by the manufacturer. Since then, I've been casting my own bullets for .500 Jeffery.

Reloading the .500 Jeffery

Reloading the .500 Jeffery