Ysterhout Dot Net

Reloading snake shot in a revolver

Felt wads and lead balls, from muzzleloader supplies. Wads are .45 caliber, balls are .440.

This shot is 2mm diameter.

Wads and balls were bought from Tactical Quarter Master. Delivery was within 3 days of ordering online.

The wads are quite thick, they can be divided into two or three with a craft knife, and still function correctly.

The wad in this picture is half it's thickness as supplied.

Using 8 grains of MP200, with a felt wad on top of the powder to hold it down, and prevent the powder and shot mixing in the case.

The amount of shot is not measured, just put enough in the case so that there is space for the lead ball to be seated. In this case, leaving about 5mm between the level of shot and the case mouth worked fine.

There are just over 90 pellets in each case.

The lead ball is too soft to use a normal bullet seating stem.

When seating the bullet flows into the seating stem cavity and sticks there.

A case expander has a flat base, which works better to seat round lead bullets.

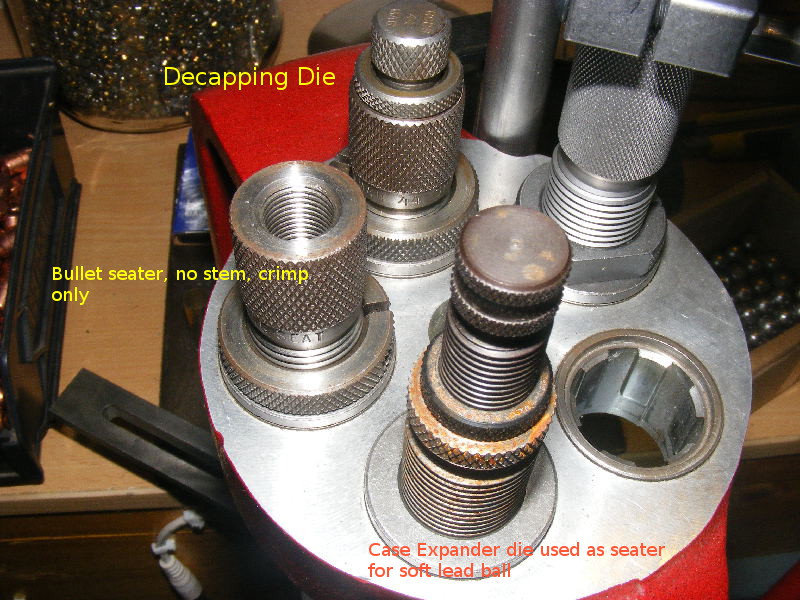

A normal decapper is used to decap and resize.

The seating die is replaced with the case expander, which is used to seat the lead balls.

The normal seating die has the seating stem removed, and acts as a crimp only. One-quarter turn crimp works fine with this seating die, which is Lyman.

After seating, there is lead around the case mouth where the ball is deformed.

Seat the ball deep enough so that more than half of it is in the case. If the lead ball is not seated deep enough, the crimping stage will cause it to jam on the crimp groove, and the ball will remain in the die.

All the loaded rounds, seated, not crimped yet. Except for the three rounds back right which were the test pilots.

All the loaded rounds crimped.

Use a nylon pot scourer to clean the loaded rounds.

There is a fair amount of lead on the round after crimping, some bits will stick to the sidewall.

Use a nylon scouring pad to clean it up.

This batch was loaded on a progressive press, but it is not recommended. These reloads should be done on a single stage.

Reason being the fine lead shavings get into places where they shouldn't on the shellplate and under it, and are tough to get rid of.

Seat the lead bullet past it's circumference into the case. If the seating is not deep enough the bullet comes undone in the crimp die.

After crimping and cleaning, check that every round fits into the cylinder. If the round is not crimped properly, or if it is not clean, it may not chamber.

At five meters [ 5.5 yards ], most of the shot is within the 0-down ring of an IDPA target, which is 20 centimeters [ 8 inches ] in diameter.

Lead ball impact is center.

A couple of shots produced significant fouling in the first two inches of a four inch .44 Magnum barrel.

Revolver Snake Shot

Revolver Snake Shot