Ysterhout Dot Net

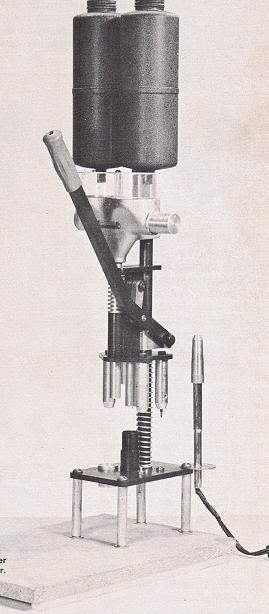

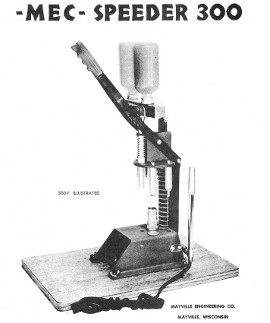

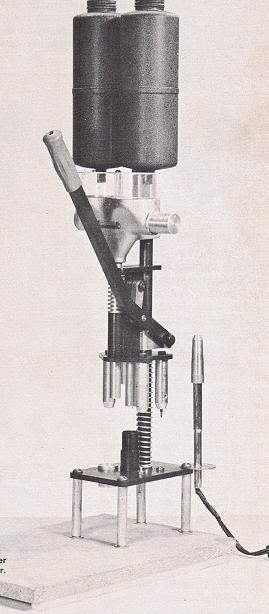

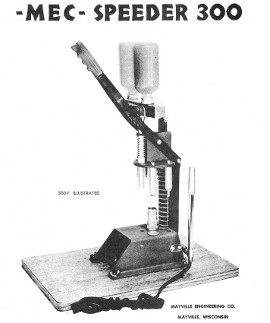

The catalog picture of the press, the actual press, and the first MEC for comparison.

Ysterhout Dot Net

The catalog picture of the press, the actual press, and the first MEC for comparison.